A little story about liquid lead…

Liquid lead has been used as a coolant for SMRs on submarines since the late 1960’s.

The use of lead enabled the reactor to be extremely compact and light, since the physical properties of liquid lead made it possible to achieve natural circulation in a small vessel. Lead would cool the system and simultaneously function as a natural shield against radiation.

It worked very well, except for that liquid lead is highly corrosive to stainless steel, and would erode the surrounding reactor vessel. For decades, this was a problem that made lead-cooled SMRs expensive in relation to their reactor lifetime.

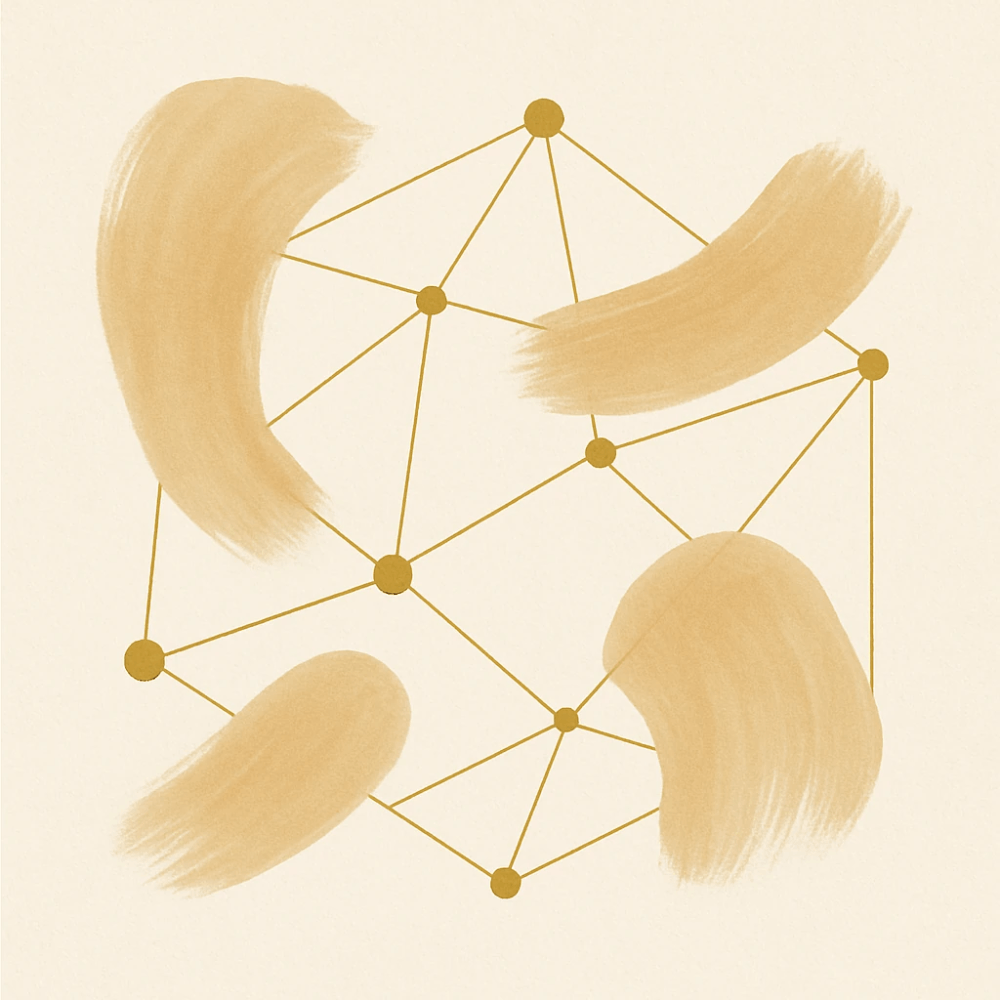

In 2013, it is developed an aluminum alloyed steel exhibiting perfect corrosion resistance, based on many years of research. This new steel perfectly protects core components against corrosion - thereby solving the historical number one challenge with lead-cooled reactors.

Ten years later, we are thrilled that the first industrial batches of this steel for our core simulator, photographed below, are on their way to our testing facilities.