Challenges in the global supply chain

Challenges in the Global Supply Chain: Navigating Complexity in a Connected World

The global supply chain is the backbone of modern commerce, enabling goods, services, and resources to flow across borders seamlessly. However, its intricate network of interdependencies also makes it vulnerable to a wide range of disruptions. Recent years have highlighted the fragility of global supply chains, with challenges stemming from geopolitical tensions, natural disasters, and the COVID-19 pandemic underscoring the urgent need for resilience and adaptability. This document delves into the key challenges facing the global supply chain, their root causes, and potential strategies to mitigate their impact.

1. Disruptions from Geopolitical Tensions

Geopolitical conflicts, trade wars, and shifting policies have significantly impacted the global supply chain. For instance, tariff impositions and trade restrictions can increase costs and delay shipments. The U.S.-China trade war, Brexit, and tensions in Eastern Europe have created uncertainties for businesses relying on cross-border trade.

- Sanctions and Trade Barriers: Sanctions imposed on specific countries or regions can disrupt the flow of goods and raw materials, forcing companies to find alternative suppliers.

- Policy Shifts: Sudden changes in trade agreements or export/import regulations can destabilize supply chain operations, particularly for industries reliant on international trade.

2. Supply Chain Bottlenecks

Bottlenecks occur when the demand for goods outpaces the supply chain's capacity to deliver them. This issue became particularly evident during the COVID-19 pandemic, which disrupted manufacturing, shipping, and logistics globally.

- Port Congestion: Overburdened ports and limited infrastructure can delay the transportation of goods, leading to increased costs and longer lead times.

- Labor Shortages: A shortage of skilled workers in key sectors such as logistics, manufacturing, and transportation exacerbates delays and inefficiencies.

3. Raw Material Shortages

Many industries face challenges in securing critical raw materials due to fluctuating demand, geopolitical tensions, and environmental constraints. The semiconductor shortage, for example, has impacted industries ranging from automotive to electronics.

- Resource Scarcity: Finite resources like rare earth metals and minerals essential for high-tech products are becoming increasingly difficult to source.

- Dependency on Single Suppliers: Over-reliance on a single region or supplier for critical materials increases vulnerability to disruptions.

4. Climate Change and Natural Disasters

Climate change has a direct and far-reaching impact on the global supply chain. Natural disasters such as hurricanes, floods, and wildfires disrupt production facilities, transportation networks, and distribution channels.

- Weather-Related Delays: Extreme weather events can damage infrastructure, delay shipments, and disrupt manufacturing operations.

- Rising Costs: The need to adapt to climate change, such as investing in sustainable practices and resilient infrastructure, adds to operational costs.

5. Technological Vulnerabilities

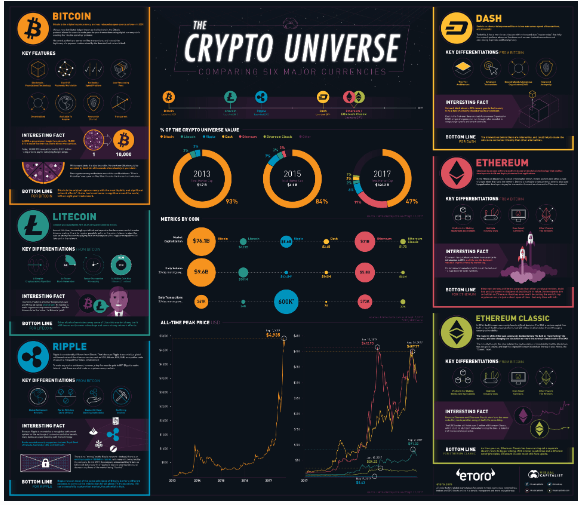

While digitalization has revolutionized the supply chain, it has also introduced new vulnerabilities. Cyberattacks targeting supply chain networks have become increasingly sophisticated, posing significant risks to businesses.

- Cybersecurity Threats: Attacks such as ransomware can cripple supply chain operations, as seen in incidents like the Colonial Pipeline attack.

- Dependence on Legacy Systems: Outdated technologies and insufficient integration across the supply chain create inefficiencies and expose vulnerabilities.

6. Rising Costs and Inflation

The global supply chain is grappling with rising costs for transportation, labor, and raw materials. Inflationary pressures are making it more expensive to produce and deliver goods.

- Shipping Costs: The cost of ocean freight and air cargo has surged, driven by high demand and limited capacity.

- Energy Prices: Volatility in energy markets, particularly oil and gas prices, adds to transportation and production costs.

7. Consumer Expectations

Today’s consumers demand faster delivery, greater transparency, and environmentally friendly practices. Meeting these expectations adds complexity to supply chain management.

- E-Commerce Growth: The surge in online shopping has increased the demand for last-mile delivery solutions, straining logistics networks.

- Sustainability Requirements: Consumers and regulators are pushing for greener supply chains, requiring companies to adopt sustainable sourcing and transportation practices.

8. Global Pandemic Impact

The COVID-19 pandemic exposed the fragility of global supply chains, with widespread disruptions affecting nearly every industry.

- Factory Shutdowns: Lockdowns and restrictions forced the closure of manufacturing facilities, disrupting production schedules.

- Shift in Demand Patterns: Sudden changes in consumer behavior, such as the surge in demand for medical supplies and e-commerce, created supply-demand imbalances.

Mitigation Strategies and Future Directions

Addressing the challenges in the global supply chain requires a multifaceted approach that emphasizes resilience, innovation, and collaboration. Key strategies include:

1. Diversification of Suppliers

- Reducing dependency on single suppliers or regions by diversifying sourcing strategies helps mitigate risks from disruptions.

- Developing local or regional supply chains can reduce reliance on long-distance transportation and enhance resilience.

2. Investment in Technology

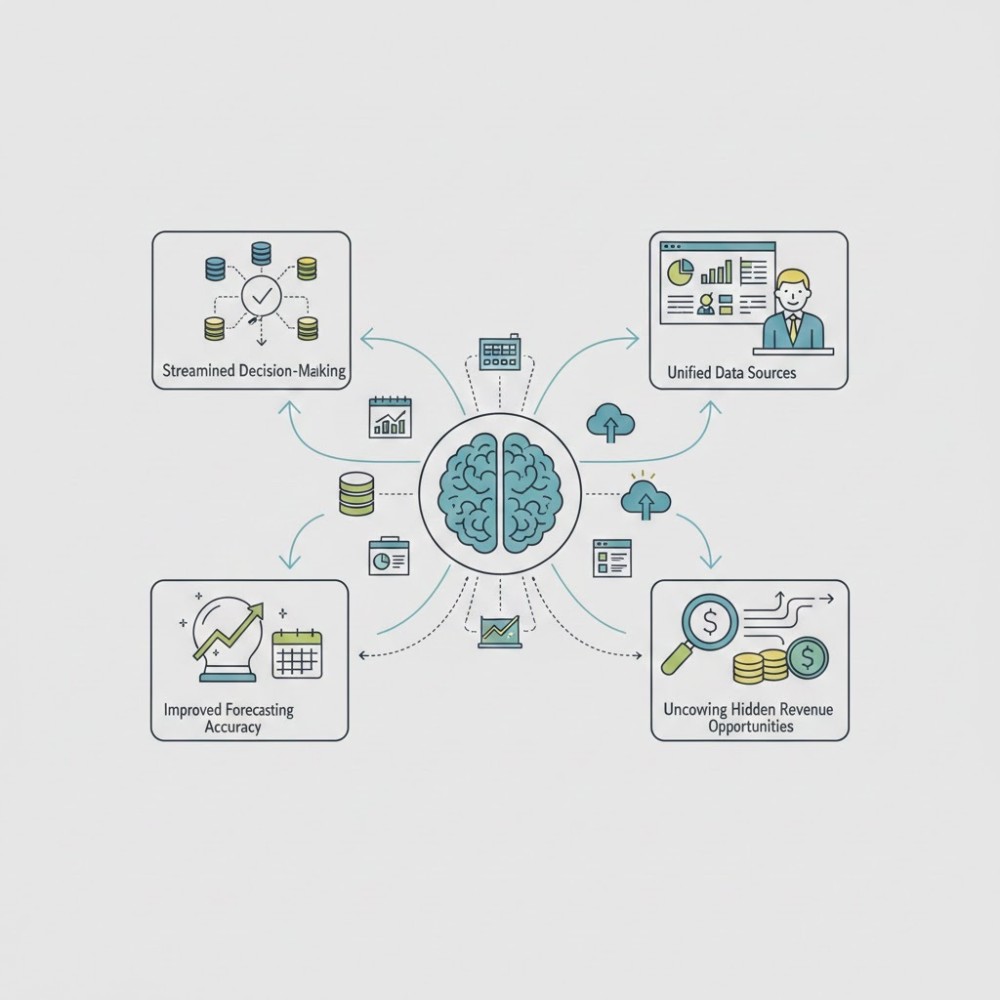

- Implementing advanced technologies like artificial intelligence, blockchain, and IoT can improve supply chain visibility, efficiency, and security.

- Predictive analytics can help companies anticipate disruptions and optimize inventory management.

3. Sustainability and Circular Economy

- Adopting sustainable practices, such as using renewable energy and recycling materials, can reduce environmental impact and ensure compliance with regulations.

- Circular economy models that emphasize reusing and repurposing products can minimize waste and resource consumption.

4. Strengthening Cybersecurity

- Investing in robust cybersecurity measures, such as encryption and real-time monitoring, can protect supply chain networks from cyber threats.

- Regular audits and employee training programs can enhance preparedness against potential attacks.

5. Collaboration and Partnerships

- Building strong relationships with suppliers, logistics providers, and other stakeholders fosters greater collaboration and information sharing.

- Public-private partnerships can address systemic challenges, such as infrastructure development and regulatory alignment.

6. Resilience Planning

- Developing contingency plans and stress-testing supply chain operations can improve preparedness for unforeseen disruptions.

- Maintaining strategic reserves of critical materials and components can help buffer against supply shortages.

Conclusion

The challenges facing the global supply chain are complex and multifaceted, but they also present opportunities for innovation and growth. By embracing advanced technologies, fostering collaboration, and prioritizing sustainability, businesses can build resilient and agile supply chains capable of navigating an increasingly unpredictable world. As globalization continues to evolve, the ability to adapt and address these challenges will determine the success of supply chain networks in the years to come.