What The Tech?! Industrial Robots

Industrial Robots helped to make the Industrial Revolution more efficient

When you say the word “Robot” it evokes images of the cyborgs from I Robot. Or possibly visions of Data from Star Trek. Or, if you’re a movie fan then perhaps the T-1000 from the Terminator series. The T-1000 made Terminator 2 a great film. Source: Wikipedia

The T-1000 made Terminator 2 a great film. Source: Wikipedia

However, there’s a far more mundane series of robots that came to life, providing us with a way to streamline food production methods, increase manufacturing line efficiencies in the automobile industry and even conduct things like surgeries and other medical procedures.

They are known as industrial robots, and without them, our means of manufacturing and shifting goods would struggle to reach efficiency levels like we see today. They’ve been an essential part of human evolution and they contain electronics, automation and other precision elements, all things that we love for What the Tech?! pieces. Let’s get started.

The Beginning

The foundations for the modern production line were laid in the early 1900s when the Ford Motor Company laid the groundwork for the first industrial assembly line. Human-powered, the line provided a way to increase productivity and manufacturing precision, to deliver large quantities of Model T vehicles to the civilian market.

Revolutionizing manufacturing, the process worked on a moving assembly line where vehicles would move through, station by station with each station providing a specific process to the vehicle. The Model T assembly line introduced the first robots. Source: Wikipedia.

The Model T assembly line introduced the first robots. Source: Wikipedia.

The process allowed for a lower-skilled workforce, with each station being trained in a single task, rather than undergoing extensive and specialized training. The benefits of this new process were vast, and using the new method the overall manufacturing time for a vehicle was slashed. Requiring around 12 hours for assembly initially, the assembly line technique dropped this to reach a peak efficiency of a vehicle every 93 minutes during 1914.

Given the advancements of the new methods, it didn’t take long for producers to look at other industries that may benefit from the same technique. While the technology didn’t exist for single-use robots back then, the idea was raised for the first time in the 1930s when the concept of a single-use machine to perform mainstream tasks first entered mainstream thinking.

Inventors and producers spent nearly two decades researching the process and designing workable concepts, and by the time the 1950s rolled around the concepts had gone from idea to working prototype.

The first serious prototype was known as the Unimate, provided by manufacturer Unimation and was designed to provide spot welding to vehicles on production lines. It was also capable of being configured for Die Casting and other useful engineering methods. The system relied on being configured for repetitive, and simple movements, a role for which, it performed admirably. The Unimate was an essential step on the road to providing more modern industrial robots. Unimate pouring a cup of coffee in 1967. Source: Wikipedia.

Unimate pouring a cup of coffee in 1967. Source: Wikipedia.

And while the usage of robots into the 70s persisted, it would take until the 1980s before the adoption of the technology would hit the mainstream.

Mainstream Manufacturing

As we entered the 1980’s they suddenly provided us with “big things”. Music artists provided big sounds, along with hair to match, and the rise of the compact disc brought music and big boom boxes into modern fashion.

Our industrial robots were not immune to this trend, becoming more expensive and complex as well as larger to boot. However, due to advances in automation, they became more precise and more efficient. Every manufacturer's dream!

The best example of this would be seen by looking at the consumer electronics industry. While we’ve spoken about the transistor in this past piece the ability to provide smaller, surface mount systems was established by the precision of manufacturing techniques in this era.

It was also around this time that automated technology took a huge leap forward with many iconic industries relying on automation to either increase efficiency or reduce workforces. There were several iconic systems through this time that allowed us to take this leap forward, most of which aren’t particularly well known publicly. Industrial Robot working in a foundry. Source: Wikipedia.

Industrial Robot working in a foundry. Source: Wikipedia.

Firstly, the advances in computing meant that the SCADA format became more mainstream, providing ways to communicate with and control industrial technology. This format continues to be used today, and SCADA security has become particularly important in cyber security roles. We see the results of insecure SCADA systems with the evolution of the STUXNET virus, an attack on the Iranian nuclear research program.

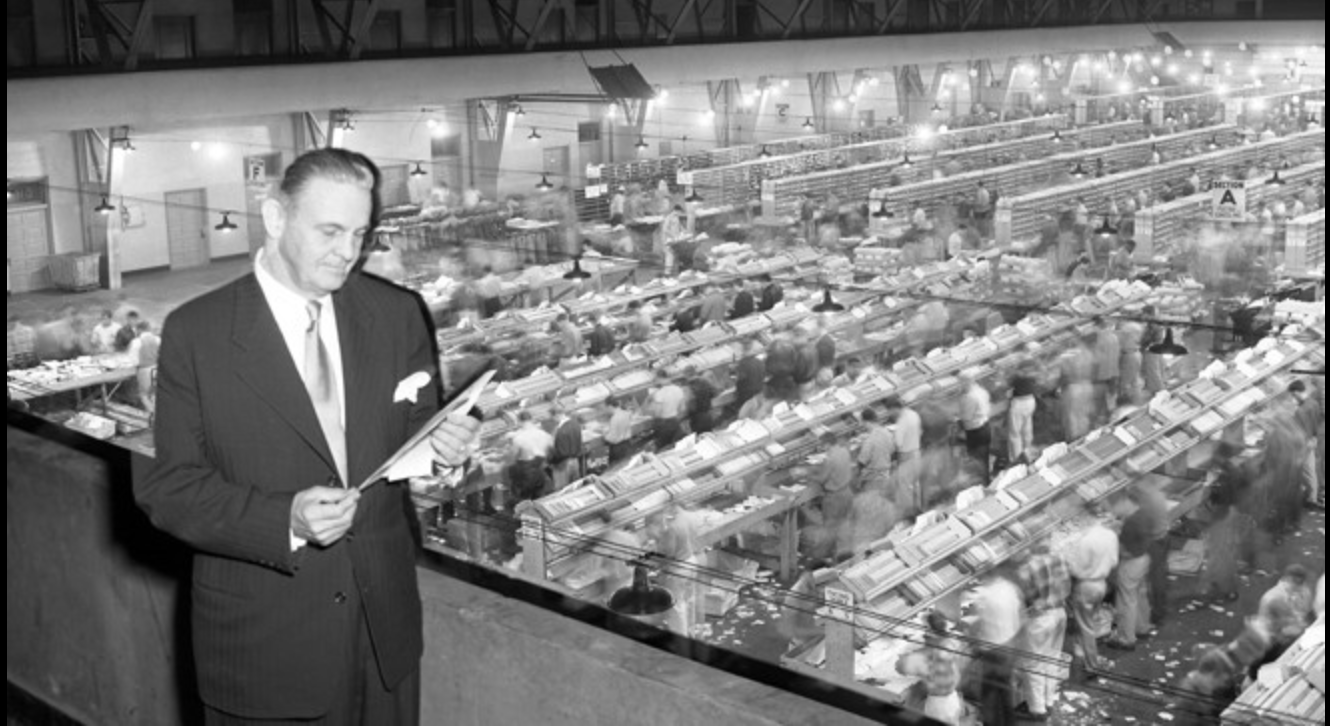

Robotic technology continued to be developed by many Western nations, and as such, we saw notable industry players from multiple countries. In Germany, KUKA provided systems that were renowned for their reliability, and performance. In Japan, FANUC industrial systems were used to provide manufacturing systems for the automotive and electronic industries. And thanks to the magic of multi-national joint ventures, Switzerland and Sweden had the IRB6 system. Smarter robots with greater precision made scenes like this LA mail sorting line a thing of the past. Source: Wikipedia.

Smarter robots with greater precision made scenes like this LA mail sorting line a thing of the past. Source: Wikipedia.

As the 1990’s descended upon us, we started then to see Robots move into more mainstream usage as systems for things like package sorting, and inventory management was able to be automated with no human intervention.

Looking into the Future

As we’ve looked at the history of technology, we’ve mostly explored the industrial side that helps with manufacturing processes. However, as the 2000s evolved we saw more investment in using the technology for automated logistical services. And while this initially started with warehousing and inventory management/shipping systems, eventually we saw it creep into things like hospitals.

While your first thought might be that they assisted with imagery and surgical processes, while you are right they also moved into things like patient meals as well. More modern hospitals will often incorporate things like food delivery into automated services, allowing a faster and more efficient delivery service. Amazon took a particular interest in robotics for its warehouses. Source: Wikipedia.

Amazon took a particular interest in robotics for its warehouses. Source: Wikipedia.

As technology evolves however the rise of the smartphone, artificial intelligence and improved visual imagery will continue to be adapted into industrial robots. This should give us machines that are more accurate, as well as being more flexible (important for industrial processes) and smarter.

We can also expect a new focus on security with our new industrial robots. While STUXNET laid the foundations for the first industrial cyber attack, it also proved the importance of securing modern manufacturing technology correctly. Given the rate at which cyber warfare has evolved, it’s fair to say that in times of crisis, critical manufacturing systems may be at risk.

In fact, the importance of getting this right can actually be seen within the evolution of cyber security right now. While typically, you’ll think of cyber security roles being things like pen testing or working in a SOC, actually securing things like SCADA systems has evolved to become a specialty. The Siemens S7–300. Stuxnet’s target of choice. Source: Wikipedia.

The Siemens S7–300. Stuxnet’s target of choice. Source: Wikipedia.

It’s why working with technology can often be rewarding. There are plenty of specialized roles that revolve around learning about your topic of relevance, in depth and then passing that knowledge along to others.

We’ll close out the article though with a philosophical question for our Into the Future segment. With the introduction of things like artificial intelligence, we’ll see more technology move into the mainstream while it lurks behind the scenes. But with things like automation in planes and vehicles, as well as a proliferation of smart devices it’s a fair question to ask if the definition of an industrial robot has evolved as the technology has.

More a rhetorical question rather than requiring any specific answer, one thing it does do is make us consider just how far technology has come, as well as just how much we rely on it for our day-to-day world.

A thought-provoking topic, wouldn’t you say?

What the Tech?! is our recurring, twice monthly piece that explores the technology that was essential in shaping our modern world.

Medium has recently made some algorithm changes to improve the discoverability of articles like this one. These changes are designed to ensure that high-quality content reaches a wider audience, and your engagement plays a crucial role in making that happen.

If you found this article insightful, informative, or entertaining, we kindly encourage you to show your support. Clapping for this article not only lets the author know that their work is appreciated but also helps boost its visibility to others who might benefit from it.

🌟 Enjoyed this article? Support our work and join the community! 🌟

💙 Support me on Ko-fi: Investigator515

📢 Join our Telegram channel for exclusive updates or.

🐦 Follow us on Twitter and

🟦 We’re now on Bluesky!

🔗 Articles we think you’ll like:

- Software Defined Radio & Radio Hacking

- OSINT Unleashed: 5 Essential Tools for Cyber Investigators

✉️ Want more content like this? Sign up for email updates here