SMT (Surface Mounth Technology)

What is this SMT?

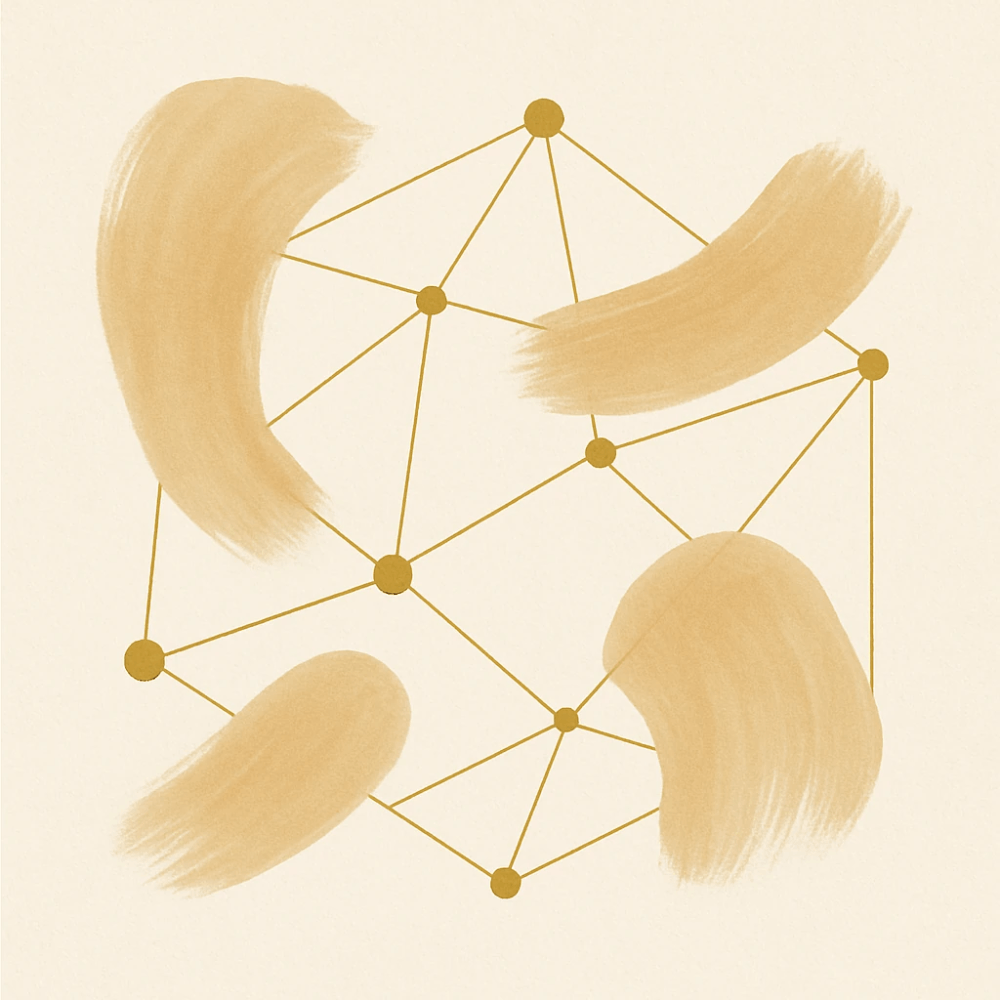

It appears as Surface Mount Technology. In short, it is a system in which electronic components are mounted on the surface instead of a perforated plate.

Why use SMT instead of through-hole plate?

-Space Efficiency: SMT allows for a much larger component density on the PCB compared to through-hole technology. This allows smaller and more compact electronic devices to be produced.

-Higher Speed and Efficiency: SMT assembly processes are generally faster than through-hole assembly. This increased speed can lead to higher overall production efficiency.

-Cost-Effectiveness: SMT can be more cost-effective in terms of material usage, as smaller and lighter components are often less expensive. Additionally, the automated nature of SMT assembly reduces labor costs.

-Automated Assembly: SMT is highly amenable to automation, allowing for efficient and precise component placement. Automated pick-and-place machines can rapidly place components on PCBs, enhancing overall production speed.

In short, it can offer us such advantages. In our next blog we will take a look at the automatic machines used.