Digital Twins: Creating Virtual Models for Real-World Optimization

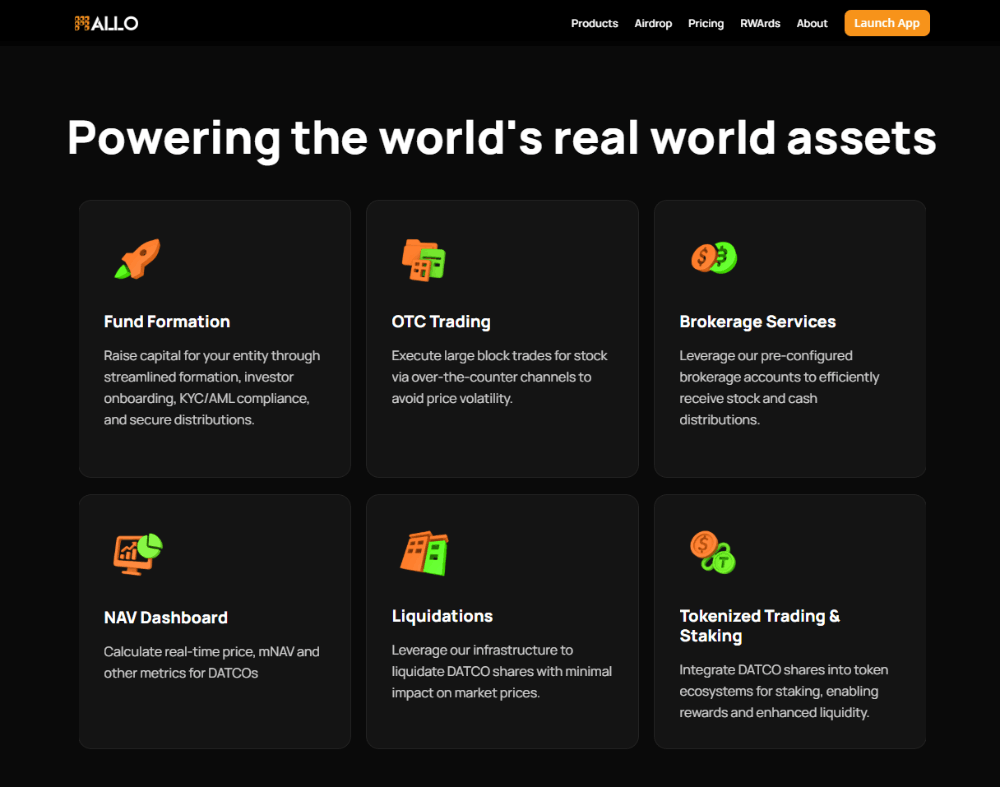

In the era of technological advancements, the concept of digital twins has emerged as a transformative force, revolutionizing various industries. A digital twin is a virtual representation of a physical object or system, utilizing real-time data to simulate, analyze, and optimize its performance. This technology has found applications across diverse sectors, from manufacturing and healthcare to urban planning and beyond.

Understanding Digital Twins

At its core, a digital twin is a dynamic, data-driven model that mirrors the physical entity it represents. It goes beyond traditional computer-aided design (CAD) models by incorporating real-time data from sensors, IoT devices, and other sources. This constant influx of information allows the digital twin to evolve and adapt, providing an accurate reflection of the actual system.

Applications Across Industries

1. Manufacturing and Industry 4.0:

Digital twins play a pivotal role in Industry 4.0, where smart factories leverage interconnected technologies for optimal efficiency. Manufacturers use digital twins to simulate production processes, predict maintenance needs, and optimize supply chains. This not only reduces downtime but also enhances overall productivity.

2. Healthcare:

In healthcare, digital twins enable personalized medicine by creating virtual models of patients. These models can simulate the impact of different treatments, helping healthcare professionals make informed decisions. Additionally, digital twins are utilized for designing and testing medical devices, improving their accuracy and safety.

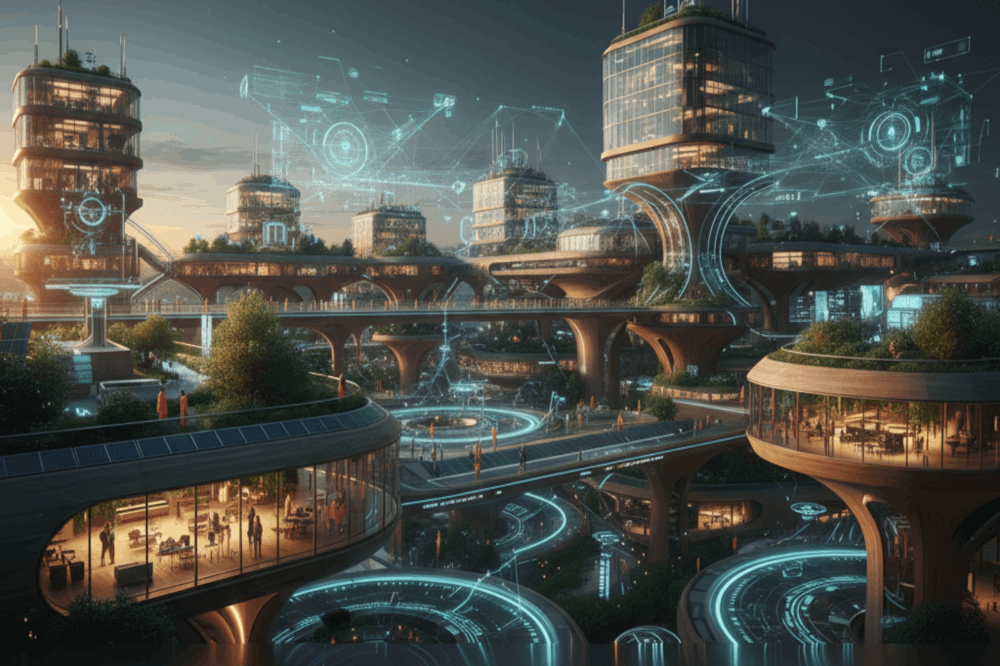

3. Urban Planning:

Cities are becoming smarter with the integration of digital twins in urban planning. These models simulate traffic flow, energy consumption, and environmental factors, aiding city planners in making data-driven decisions. The result is more sustainable and efficient urban development.

Benefits of Digital Twins

1. Predictive Maintenance:

Digital twins empower industries to predict equipment failures before they occur. By monitoring the real-time performance of physical assets, organizations can schedule maintenance activities proactively, reducing downtime and minimizing costs.

2. Improved Design and Innovation:

In the design phase, digital twins allow for thorough testing and refinement before physical implementation. This not only accelerates the product development cycle but also enhances innovation by providing a platform for experimentation without real-world consequences.

3. Enhanced Decision-Making:

The wealth of real-time data generated by digital twins facilitates informed decision-making. Whether optimizing manufacturing processes, managing healthcare interventions, or planning urban infrastructure, decision-makers can rely on accurate and up-to-date information.

Challenges and Future Outlook

While the benefits of digital twins are significant, challenges such as data security, interoperability, and the complexity of integrating diverse systems remain. As technology evolves, addressing these challenges will be crucial for the widespread adoption of digital twins.

Looking ahead, the future of digital twins seems promising. Advancements in artificial intelligence, machine learning, and connectivity will likely refine the capabilities of digital twins, making them even more integral to the optimization of real-world systems.

Digital twins represent a paradigm shift in how we approach and optimize complex systems. By creating virtual replicas that evolve alongside their physical counterparts, organizations can achieve unprecedented levels of efficiency, innovation, and sustainability. As we continue to unlock the full potential of this technology, digital twins are poised to redefine the way we interact with and optimize the world around us.