Understanding the Basics of High Pressure Liquid Chromatography

High Performance Liquid Chromatograpy (HPLC)

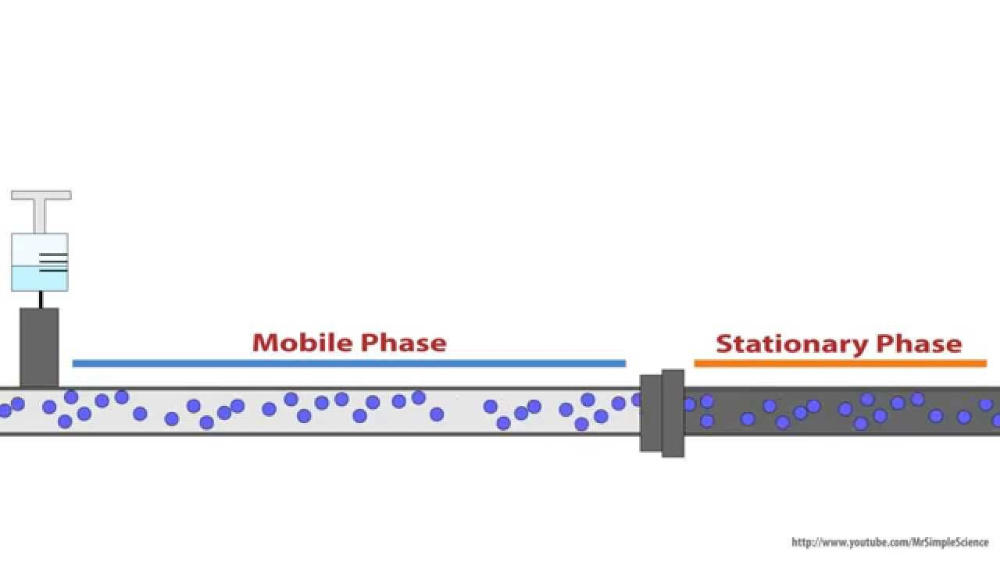

In early studies in high performance liquid chromatography, stationary phases of 100-250 µm size were used and the aim was to make the mobile phase pass through this stationary phase by using the force of gravity, but due to the size of the stationary phase, this process took time and gave wide bands. Thanks to the research and developing technology, high pressure has been replaced by gravitational force and the size of the stationary phase has been reduced to 3-5 µm. As a result, high pressure liquid chromatography was achieved.

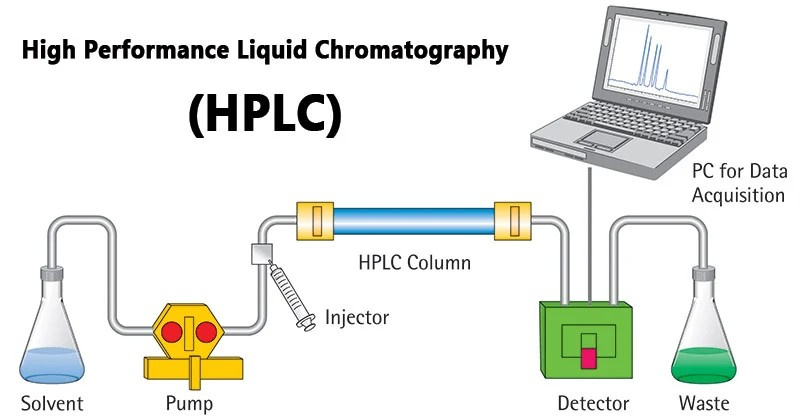

With this method, the separation of organic and inorganic compounds of various foods, drugs, and biological samples is ensured. This method is an expensive method due to the supply of mobile phase, but it has many advantages. For example, the column can be used repeatedly for discrimination, it is compatible with detectors working with different principles, and the repeatability of analysis results is very high. An HPLC device may include a mobile phase tank, syringe, pump, separation column, detector, computerized signal receiver, and a column heater that may be required for some special cases. The analysis phase in HPLC begins with injecting the dissolved substances in the adjusted solvents into the device with the help of an injector. The basic and most important point in the system is the separator column section. The substances coming to the column are separated here and send signals to the detector, and at the last stage, chromatogram graphics are detected.

Mobile Phase : The part that drags the substances we analyze in the stationary phase is the mobile phase. The mobile phase generally consists of water and aqueous buffer solutions, their solutions formed with methanol or acetonitrile, or organic solvents. The composition of the mobile phase and pH value directly affect the separation; the mobile phase should be selected according to the technique used, sample type, column and detector. For example, if normal phase chromatography is to be used, mobile phase solvents must be nonpolar.

Pump : It is the must-have part in the HPLC device. It is the part that ensures continuous movement or fluidity of the mobile phase and the substance to be analyzed throughout the column, injector and detector. As can be understood from here, the general duty of the pump is to ensure that the liquid remains in circulation continuously. Pumping mechanisms in HPLC systems are divided into certain classes. These classes can be determined based on the flow rate, the material the pump is made of, and the basis of conveying the mobile phase of the pump.The pump in an HPLC device must be resistant to pressure up to 350-500 atm. Another feature is that it ensures that the flow rate is at the desired levels.

Detector : This part of the device is the part where research and studies bear fruit, that is, the results are followed. This is the part where the data obtained is uploaded to the system and monitored, and various graphics are designed. These structures must have the ability to reveal the desired substance as it progresses through the column. Values should provide an equal and accurate approach to every outcome. It should not be affected by environmental factors. Fluorescence detector, conductivity detector, refractive index detector, electrochemical detector and chemical detectors have been developed.

Column : In general, most HPLC columns are made by reinforcing various elements that are resistant to the harmful effects and corrosion of the mobile phase passing through the interior and can withstand the pressure generated during analysis. The column internal structure must be in compliance with the desired criteria and values. Column sizes vary greatly from each other. These dimensions vary depending on the methods to be used.This part, which is one of the arteries of the HPLC device, is the region responsible for the separation of substances from each other with a good method and good resolution in mixtures containing many different numbers of samples. Care should be taken to ensure that the materials that form the inner surface of the column, the method to be used, and the substances to be investigated are compatible with each other. As the diameter of the column to be used increases, the flow rate and filling capacity will increase, but its sensitivity, that is, the resolution of the peaks, decreases. The length of the column is also a separate parameter. As the column length increases, the separation of the substances to be analyzed is better, but in this case, there is a visible increase in the amount of spent mobile phase.

Injection Loop : This is the part responsible for transferring the sample to be analyzed to the device. There are two types of injectors in HPLC devices: manual or command-supported automatic injectors. Today, thanks to advancing technology, automatic injector units are now available in many different functional features.

Column Oven : In order for the research and studies to yield the highest results, the places where the column is stored must be kept at certain temperatures. For this reason, column ovens are of great importance in HPLC devices. These devices are divided into subclasses according to their various features.

Below you can see the graph of a product analyzed.

THANK YOU FOR READİNG

![Nekodex – Earn 20K+ NekoCoin ($20) [Highly Suggested]](https://cdn.bulbapp.io/frontend/images/b4f0a940-f27c-4168-8aaf-42f2974a82f0/1)