The Unique Flagship of the Industrial Armament, CNC Machinery.

The Unique Flagship of the Industrial Armament, CNC Machinery.

Development, rise in living standards, contemporary life, civilization, etc. When examining concepts that remind humanity of its dominance and perhaps happiness in this world, we generally start from the steam boiler and therefore the invention of the locomotive, automobiles, machines, radio, television, computers, etc. We list the tools and equipment that are indicators of civilized and technological development, and at the top we generally put the developments in aviation, specifically airplanes.

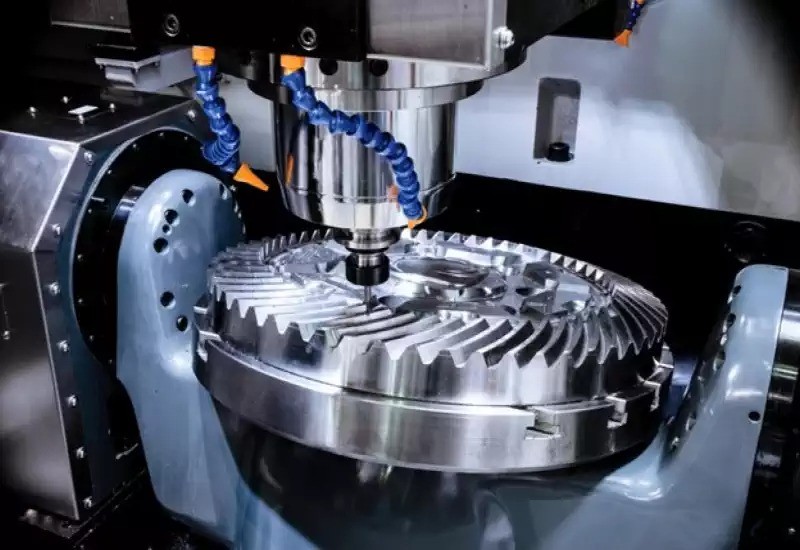

However, the most effective and efficient "catalyst" CNC machines, which create a "multiplier effect" in the dizzying industrial development especially in the last half century, are not well known by circles outside the industrial world, although they are generally well known, loved, respected and trusted in all industrial circles. The roles and contributions of technological wonders such as automobiles, ships, machines, white goods and airplanes in reaching these levels are unknown.

CNC (Computer Numerical Control) Machine; It is a computer-controlled automatic power tool for turning, milling, engraving, cutting, drilling, grinding, welding, spinning, winding in modern industrial manufacturing. A CNC Machine works with CAD/CAM software and G code for automatic machining.

The most common types of CNC machines include CNC Mills, CNC Machining Centers, CNC Lathes, CNC Drilling Machines, CNC Boring Machines, EDM Machines, CNC Drilling Machine, CNC Routers, Water Jet, CNC Laser Machines, CNC Grinders, CNC Welding Machines, CNC There are Benders, CNC Winding Machines, CNC Spinning Machines and CNC Plasma Cutters.

Computer numerical control (CNC) is a method of automating the operation of machine tools by using computers to control their movements. Rather than relying on manual techniques or mechanical devices, CNC systems use software programs to control the manufacturing process.

The technology processes a wide range of materials, including metals, plastics and wood, allowing the creation of all types of items, from precision parts to large-scale production.

Origins of CNC,

CNC technology was first developed for the military industry in the 1940-50s. It was used to control the movement of large machine tools such as lathes and milling machines in the process of making parts for military equipment. The use of CNC machines in machining operations has rapidly spread to other industries, including the automotive and aerospace industries.

How Does CNC Technology Work?

In CNC technology, computers are used to control the movement of machines. The computer program that controls a CNC machine is called a "part program". A part program consists of a set of coded instructions that tell the machine what to do. The machine then follows these instructions to shape or cut the material being processed.

The CNC machine consists of many major components, including the machine tool, tool holder and control system. A machine tool is the device that performs actual machining operations, such as cutting or drilling. A tool holder is the device that holds the cutting tool in place. The control system is the computer that runs the part program and sends commands to the machine tool and tool holder.

CNC machines; Depending on their capacity, they can process parts in 1, 2, 3, 4, 5 axes. Thus, a CNC machine can include several lathes, milling machines, planers, etc. It can do the processes that machines need to do on its own.

What are the Advantages of Using CNC Technology?

CNC machines have many advantages over traditional machines, the main ones being;

High manufacturing accuracy and precision; CNC machines can produce much more precise parts than traditional machines.

Less risk of human error; As long as CAD (Computer Aided Design), CAM (Computer Aided Manufacturing) processes are smooth and CNC software (G Coding) is entered properly, human error is not very possible in CNC manufacturing.

Ability to produce complex parts quickly and efficiently; CNC machines can be used to create a wide variety of parts and shapes, making them very versatile.

Less waste and material use; In manufacturing with CNC, wastage is almost "0" compared to classical machining machines.

Improved consistency and repeatability; CNC machines can produce the same parts over and over again.

Lower Labor Costs; Since CNC machines are automatic, they require less labor than traditional machines.

Additionally, CNC machines can be incredibly cost-effective in the long run. Although they can be expensive to purchase and expensive to maintain, they can generally produce parts at a lower cost per unit than traditional production methods.

What Will Be the Future of CNC?

So, what awaits CNC technology in the future? As with any technology, it's hard to predict exactly where this will go. But there are a few trends we see in the industry:

Increasing use of automation and artificial intelligence,

Integration with other advanced technologies such as 3D printing and augmented reality,

Advances in software and programming make CNC machines more precise and efficient.

One thing is for sure: CNC technology is not going away anytime soon. As the engineering industry continues to evolve and change, CNC machines will likely continue to be an integral part of the manufacturing process.

Conclusion:

CNC technology has had a significant impact and benefits on modern manufacturing processes. CNC machines have helped manufacturing industrialists design and produce high-quality parts while minimizing costs and waste by improving precision, shortening lead times, and increasing efficiency. As a tool for manufacturing parts for the aerospace industry; From its early days to today's incredibly advanced machines, CNC; It completely changed the way we think about production.

As technological advancements continue, we will see continued growth and advancements in the field of CNC technology and their impact on modern manufacturing processes. In the future; It is clear that CNC technology will continue to play important roles in the manufacturing industry.

![[LIVE] Engage2Earn: Veterans Affairs Labor repairs](https://cdn.bulbapp.io/frontend/images/1cbacfad-83d7-45aa-8b66-bde121dd44af/1)