What The Tech?! 3D Printing

3D printing has been around much longer than you’d think

One of the biggest wins around the miniaturization of small electronics has been the ability for Hobbyists and small-scale manufacturers to produce boutique or bespoke designs, quickly and cheaply. Because of this, we’ve seen plenty of changes through the years with regard to just how many of these processes work.

Most of these designs have focused on productivity improvements, with many steps removed or improved through the process, as well as new ways to batch print products, fixes, and information.

Today’s piece of technology revolutionized the printing world, provided new ways to manufacture small pieces of technology, and changed the way we look at small-scale manufacturing entirely. This article focuses on the development and implementation of the 3d printer. We’ll also take a look at its distant cousin, the field of Additive Manufacturing.

Early Research & Design

3d printing was a relatively late entrant to the world of technology, all things considered. However, once it arrived it changed the way we spoke and thought about small-scale manufacturing. The possible addition of the 3d printer to home worships promised large improvements in both productivity and manufacturing at scale.

Early research into the process started at the beginning of the 1980’s. However, the technology that would allow the process to flourish wasn’t readily available at this point, and despite years of research and multiple test programs it would take until the late 90s for the tech to catch up and the process to finally take off.

It’s worth mentioning though, that early 80’s 3d printers were a significant investment, typically costing hundreds of thousands of dollars for a reliable system. This investment would cost over half a million dollars when adjusted for inflation in today's dollars. Almost as much as an HP ink cartridge in the early 2000s!

While the history of printing in general is pretty fascinating on its own, the story of 3d printing is even more so. One of the things that contributed to its viability was the late 90s / early 2000s trend of desktop printers becoming cheaper and more efficient.

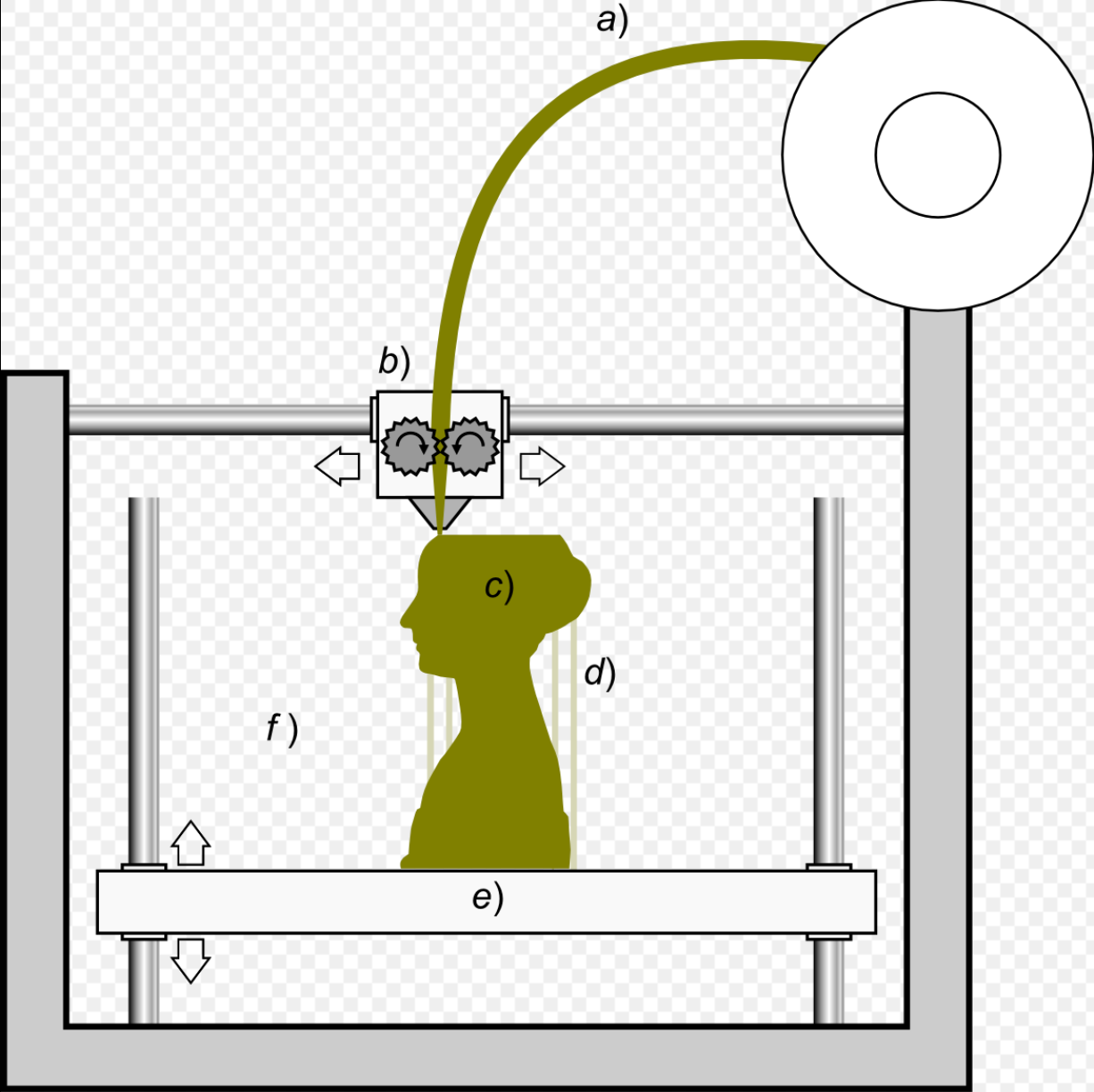

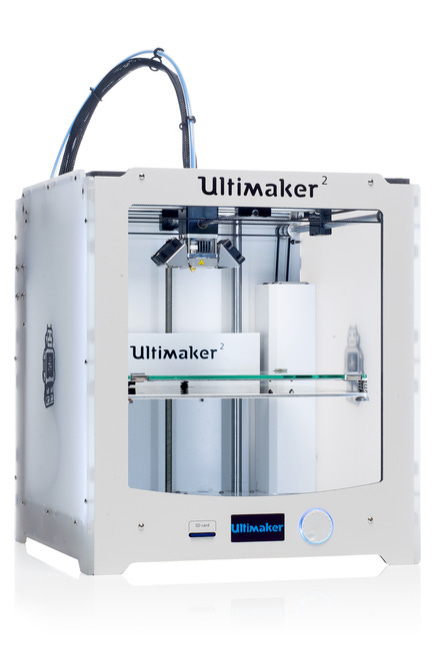

Replacing the dot matrix printers of old, the new designs showed the potential for a myriad of things to communicate via USB ports, and the square form factor designs work well for providing small-scale printers that could be used by the consumer to print different designs out of varying materials without taking up too much space in a maker lab.

The Boom Years

It’s fair to say that in this instance, we’re still currently in the boom years, figuring out how to best leverage 3d printing for manufacturing and general design improvements. Since it reached the general consumer world, we have seen larger designs printed as well as extensive research carried out in fields like food production, vehicle manufacturing, and construction. While the utility of 3d printing was instantly recognizable when the technology was first launched, it took quite some time for the depth of this permeation to become evident. If you said in the 1990s that within 10 years you’d see labs printing food and carrying out research on sustainable meat-free production, you’d have been laughed out of the room.

Yet here we are, two decades into the millennium experimenting with just that. While it’s hard to say if the process will stick around or show merit for mass adoption simply the fact that we are able to do so provides many research opportunities that simply weren't there before.

3d printers are an essential part of any maker lab. Source: Wikipedia

In our opinion, one of the craziest evolutions of the 3d printing world has been experimenting with 3d printed biomaterial.

When you think of traditional printing we use a medium for transferring that print onto another surface, such as paper, or clothing. However as well as printing inert materials like PLA and other plastics, 3d printers can print living cells, stack by stack and row by row.

This ingenious yet rather creepy creation means that the list of things that can be printed expanded dramatically. Because of this, we have seen new research into lab-grown meats that are printed in recognizable “food” shapes, as well as experimentation with human body parts for medical purposes.

While you won’t be 3d printing a replacement kidney soon, the research within these fields shows both the adaptability and ingenuity of human inventions when paired with cutting-edge technology.

Looking Ahead

In the early days, it’s fair to say that many considered the evolution of 3d printing to be little more than a fad or gimmick, something that would pass as “real” technology evolved and matured. However, it’s also fair to say that these people were dead wrong, and many failed to anticipate just how much the evolution of 3d printing would change manufacturing, making, and technical design.

Often, with new technology, it’s the military world that benefits from new technology and 3d printing was in essence, no different. While you’d typically expect it to be cutting-edge programs like robotic systems or unmanned aerial vehicles, one of the biggest benefits came from something much more humble. It’s renowned for keeping morale boosted the world over and you almost certainly use one yourself. It’s the humble coffee cup. 3d printing gave new life to an aging platform. Source: Wikipedia.

3d printing gave new life to an aging platform. Source: Wikipedia.

By the time the late 2000s rolled around the US Air Force’s venerable KC-135 platform had served decades in several key roles. Providing aerial tanker support, the platform was also adapted to the signals intelligence and command and control roles with the evolution of the E-6 Mercury and RC-135 surveillance platforms.

However, the aging platform was struggling with parts availability and due to its age many manufacturers either no longer made parts for the platform or had shut up shop entirely. So, when the plug-in coffee heaters on board the platform began to fail, the Air Force was left with a rather unique scenario.

Pay the bargain price of $1210 for a replacement, or adapt to 3d printing and make their own for a fraction of the price. The Air Force went all in on 3d printing and created their in-house design units to solve the problem. A unit that is still active to this day. Read more about this program in this link.

We’ve also seen larger and more complex prints tackled with an increased efficiency in the manufacturing process. A good example of this is Rigid Inflatable Boats (RIB), which are a key component of a modern naval force. This everyday workhorse lends itself to large-scale printing, allowing new designs to be printed cheaper and stronger than before. And we’ll continue to see this as printing continues to evolve.

The adaptation of the printing process for larger complex designs, as well as the adaption or replacement of older obsolete devices. 3d printing really does promise continuing increases in manufacturing productivity. The offending coffee cup. Source: US Airforce.

The offending coffee cup. Source: US Airforce.

The Maker

As we closed out today's article we couldn’t do so without touching on a field that passionate about. The hacker/maker community. While this community has always been about modification, individualism, and making something good, or great it’s fair to say that 3d printing came with significant benefits for this community as well. No longer would makers be foiled by broken or obsoleted parts, the savvy developer would simply print their own. But, like many other fields, it’s the explosion of data from within that allowed the community to reap the true benefits.

Like many other open-source communities, information sharing was a key part of making things work. While there was a competitive spirit, it was also understood that putting resources back into the community would benefit everyone.

When we look at this and examine the link to 3d printing, one of the most valuable assets available to the maker is the explosion of open-source format print files for nearly every device imaginable (as well as some that are unimaginable!).

This means that the only limitation to the application is creativity, and because of this in the past few years, we’ve seen some extremely ingenious designs. Like artificial intelligence, failing to consider the benefits of 3d printing runs the very real risk of being left behind by those who do.

So, with that said, the only question that remains to be asked is. What have you used 3d printing for lately? Why don’t you drop a comment and tell the world?!

Medium has recently made some algorithm changes to improve the discoverability of articles like this one. These changes are designed to ensure that high-quality content reaches a wider audience, and your engagement plays a crucial role in making that happen.

If you found this article insightful, informative, or entertaining, we kindly encourage you to show your support. Clapping for this article not only lets the author know that their work is appreciated but also helps boost its visibility to others who might benefit from it.

🌟 Enjoyed this article? Support our work and join the community! 🌟

💙 Support me on Ko-fi: Investigator515

📢 Join our OSINT Telegram channel for exclusive updates or

📢 Follow our crypto Telegram for the latest giveaways

🐦 Follow us on Twitter and

🟦 We’re now on Bluesky!

🔗 Articles we think you’ll like:

- Software Defined Radio & Radio Hacking

- OSINT Unleashed: 5 Essential Tools for Cyber Investigators

✉️ Want more content like this? Sign up for email updates here