Aluminum Composite Panels: Enhancing the Built Environment or a Risky Addition?

Aluminum Composite Panels: Enhancing the Built Environment or a Risky Addition?

Photocredit: Modern Cladding System.

Photocredit: Modern Cladding System.

Introduction

Aluminum composite panels (ACPs) have become a staple in contemporary architecture due to their aesthetic appeal and functional benefits. These panels, often seen on high-rise buildings and commercial facades, are praised for their lightweight nature, durability, and versatility. However, they have also sparked debates over their safety and environmental impact. This article delves into the production process, material composition, and ethical considerations surrounding ACPs, providing a balanced perspective on their role in the built environment.

Production and Material Composition

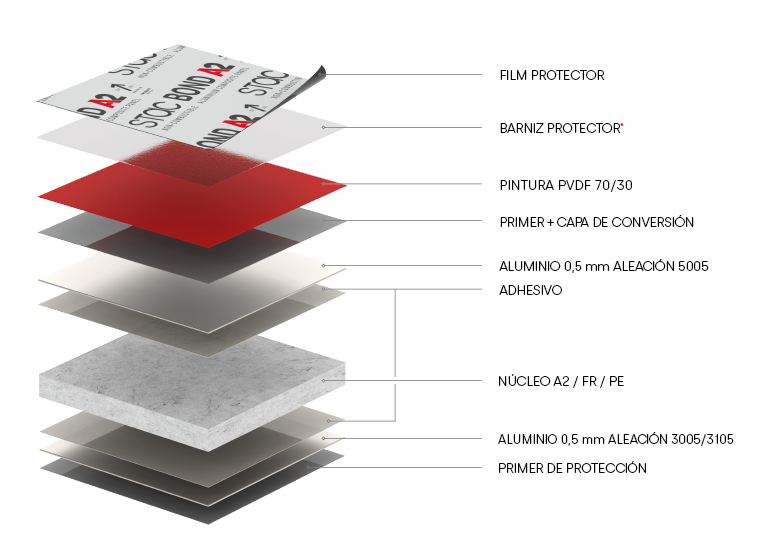

ACPs consist of two thin layers of aluminum enclosing a non-aluminum core, typically made from polyethylene (PE), mineral-filled core (MFC), or other materials designed to enhance fire resistance. The production process involves several key steps:  Photocredit: StacBond

Photocredit: StacBond

1. Preparation of Aluminum Sheets:

High-quality aluminum sheets are treated to ensure they are free from impurities and defects. These sheets are then cleaned and coated with a protective layer to enhance durability and resistance to corrosion.

2. Core Material Processing:

The core material, often polyethylene or a fire-resistant alternative, is processed to achieve the desired thickness and consistency. This core is crucial as it impacts the panel’s weight, flexibility, and fire resistance.

3. Bonding:

The aluminum sheets are bonded to the core material using heat and pressure. This creates a strong, lightweight panel that can be easily shaped and installed.

4. Surface Finishing:

The bonded panels undergo surface treatments, including painting or coating with various finishes such as PVDF (polyvinylidene fluoride) or polyester. These finishes provide the panels with their distinctive look and protect against weathering and UV radiation.

Applications and Benefits

ACPs are favored in the construction industry for several reasons:

Aesthetic Appeal:

Available in a wide range of colors and finishes, ACPs offer designers flexibility in creating modern and visually striking facades.

Durability:

ACPs are resistant to weathering, corrosion, and impact, making them suitable for various climates and conditions.

Lightweight:

Despite their robustness, ACPs are lightweight, reducing the load on building structures and facilitating easier installation.

Insulation:

They provide good thermal and sound insulation, contributing to energy efficiency and comfort in buildings.  Sources: Pinterest

Sources: Pinterest

Ethical Considerations and Concerns

While ACPs offer numerous benefits, their use has raised ethical and safety concerns, particularly regarding fire safety and environmental impact.

Fire Safety

One of the most significant concerns with ACPs is their potential fire hazard. Panels with a polyethylene core, in particular, are highly flammable. This issue came to the forefront following several high-profile fire incidents, such as the 2017 Grenfell Tower fire in London, where ACPs with PE cores contributed to the rapid spread of the fire, resulting in significant loss of life and property. In response, many countries have updated their building codes and regulations to restrict or ban the use of non-fire-resistant ACPs in high-rise buildings.

Environmental Impact

The production of ACPs involves significant energy consumption and the use of non-renewable resources. Additionally, the polyethylene core is derived from petroleum, contributing to the environmental footprint. Recycling ACPs is also challenging due to the difficulty in separating the aluminum from the core material. This raises questions about the long-term sustainability of using ACPs, especially given the growing emphasis on green building practices and materials.

Ethical Manufacturing Practices

There are ethical considerations regarding the labor practices involved in ACP production. Ensuring fair labor conditions and avoiding exploitation in the manufacturing process are crucial aspects that companies need to address. Additionally, transparency about the sourcing of raw materials and adherence to environmental regulations are essential for maintaining ethical standards.

Case Studies and Real-World Applications

Grenfell Tower, London:

The tragic fire at Grenfell Tower highlighted the dangers of using flammable ACPs in high-rise buildings. The incident led to a global reassessment of building codes and fire safety standards related to ACPs.  Photocredit: Daily Express

Photocredit: Daily Express

The Shard, London:

Conversely, The Shard in London showcases the successful use of fire-resistant ACPs, combining aesthetic appeal with safety and functionality.  Photo Credit: Trainline

Photo Credit: Trainline

Federation Square, Melbourne:

This iconic building features ACPs, demonstrating their versatility and contribution to modern architectural design while adhering to stringent fire safety regulations.  Photo credit: Viator

Photo credit: Viator

Conclusion

Aluminum composite panels present a complex interplay of benefits and risks. While they offer significant advantages in terms of aesthetics, durability, and versatility, their use raises critical ethical and safety considerations. Ensuring the use of fire-resistant materials, adhering to environmental standards, and promoting ethical manufacturing practices are essential steps in mitigating the risks associated with ACPs. As the construction industry evolves, it must balance the appeal of innovative materials like ACPs with the imperative of safety and sustainability.

References

- BBC News. (2017). Grenfell Tower fire: Combustible cladding blamed for rapid spread. Retrieved from [BBC](https://www.bbc.com/news/uk-40380584)

- The Shard. (n.d.). Facts. Retrieved from [The Shard](https://www.the-shard.com)

- Federation Square. (n.d.). Architecture. Retrieved from [Federation Square](https://fedsquare.com)