Biogas Digester Maintenance and Optimization: Ensuring Long-Term Sustainability

As the global focus intensifies on transitioning towards renewable energy sources, biogas digesters have emerged as a pivotal player in the sustainable energy landscape. This comprehensive guide delves into the nuanced realm of biogas digester maintenance and optimization, exploring key practices to ensure their long-term sustainability, efficiency, and continued contribution to a greener future.

1. Routine Inspection and Monitoring:

The cornerstone of biogas digester maintenance lies in routine inspection and vigilant monitoring. Regularly assessing the structural integrity, gas production rates, and pressure levels within the digester allows operators to identify potential issues at an early stage. This proactive approach not only mitigates risks but also facilitates the optimization of performance over time.

2. Microbial Health and Nutrient Balance:

A thriving microbial community is fundamental to the success of anaerobic digestion. Maintaining optimal conditions for microbial activity requires careful attention to nutrient balance, particularly the carbon-to-nitrogen ratio. Regular assessment and adjustment of nutrient levels ensure a conducive environment within the digester for efficient biogas production.

3. Temperature Control:

Temperature serves as a critical factor influencing the anaerobic digestion process. Implementing effective temperature control measures, such as insulation or heating systems, becomes imperative to create and sustain an environment that fosters microbial activity. This, in turn, enhances the efficiency of the digestion process and overall gas production.

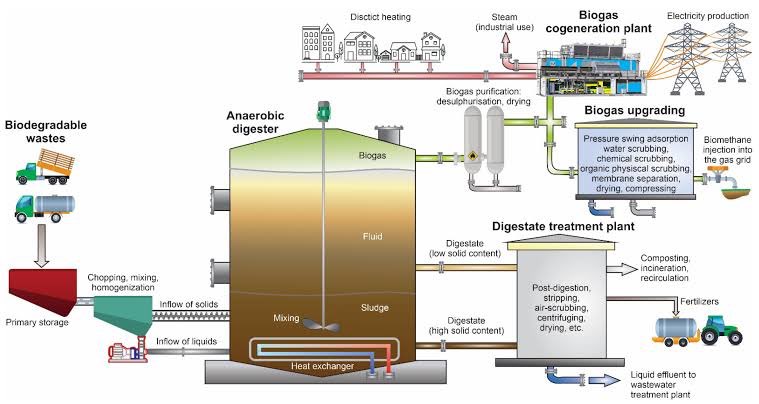

4. Gas Utilization Efficiency:

Optimizing the utilization of biogas is paramount for maximizing the benefits of a digester. Efficient gas storage and distribution systems, coupled with well-maintained appliances, contribute to the effective utilization of the produced biogas. This not only enhances energy output but also ensures economic viability.

5. Waste Feedstock Considerations:

The composition and quality of organic waste fed into the digester significantly impact its performance. Striking a balance in the mix of waste materials, avoiding contaminants, and ensuring a consistent feedstock are essential elements of stable and efficient anaerobic digestion.

6. Upgrades and Technological Advancements:

In the rapidly evolving landscape of renewable energy technologies, staying abreast of innovations is crucial for the optimization of biogas digesters. Regularly considering upgrades that leverage advancements in digester design, control systems, and monitoring tools enhances overall efficiency and adaptability to changing demands.

7. Training and Education:

The efficacy of maintenance efforts is closely tied to the knowledge and skills of the individuals overseeing biogas digesters. Establishing comprehensive training programs ensures that operators are equipped to handle routine tasks, identify emerging issues, and implement preventive measures. A well-informed workforce becomes an asset in maintaining the longevity of the digester infrastructure.

Challenges and Solutions:

While diligent maintenance practices are imperative, challenges such as the availability of skilled personnel, access to spare parts, and financial constraints can pose obstacles. Addressing these challenges requires a holistic approach involving collaboration between stakeholders, supportive policies, and ongoing research to innovate solutions.

Conclusion

Biogas digesters represent more than just an intersection of waste management and renewable energy; they embody a sustainable future. Nurturing their long-term sustainability demands a commitment to meticulous maintenance and optimization practices. By incorporating best practices, embracing technological advancements, fostering a culture of ongoing education, and addressing challenges collaboratively, societies can ensure that biogas digesters continue to be a cornerstone in building a cleaner, more resilient, and sustainable energy future.